Thermoforming / Vac Forming

All Type Plastic Fabrication can offer a number of forming options from this specialized application. Thermoforming, Vacuum, Press, Blow, and Drape Moulding are just some of the applications we offer our customers in order to achieve these results.

Thermoforming / Vac Forming

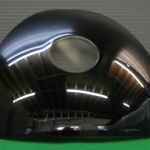

Thermoforming requires a thermoplastic sheet heated to its softening point then drawn or forced over an open mould and cooled until the shaped produced can be removed. Thermoforming is a very versatile process and is particularly economical when relatively short runs of large objects are required or when particularly thin containers are required in large quantities. Tooling and equipment is relatively inexpensive compared with other moulding processes.

Vac Forming requires a sheet to be heated and shaped by reducing the air pressure between itself and the mould. The substrate is clamped over the mould. Heater bars move directly over the plastic sheet and once the sheet has softened the heater bars are removed and a vacuum is applied beneath the sheet from inside the mould and the shape of the plastic begins to appear as it is drawn into the mould.

Blow Moulding

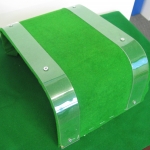

The process of blow moulding requires heat to soften the substrate and once achieved is clamped down and then blown with controlled air pressure which is released from under the substrate causing it to stretch/bow upward whilst under this pressured state. The desired bubble height is determined by the air pressure intake controlled by the machinist.

Drape Moulding or Forming

Drape forming is used for two-dimensional shapes and for mild three dimensional shapes. Once heated to the proper temperature the substrate should be removed and carefully draped over the form. The edges of the sheet will curl in the cooling process so clamps should be used. Most cooling and the best contour tolerances can be obtained if the parts are covered with a soft felt of flocked rubber blanket and is allowed to cool slowly.